The SDV Tightrope: Unmasking the True ROI & Risks of OTA Updates in Cars

OTA updates are transformational, slashing recall costs by up to 70% and turning vehicles into true “computers on wheels” —but one bad update can cost millions, spark lawsuits, & devastate reputation.

1. Introduction

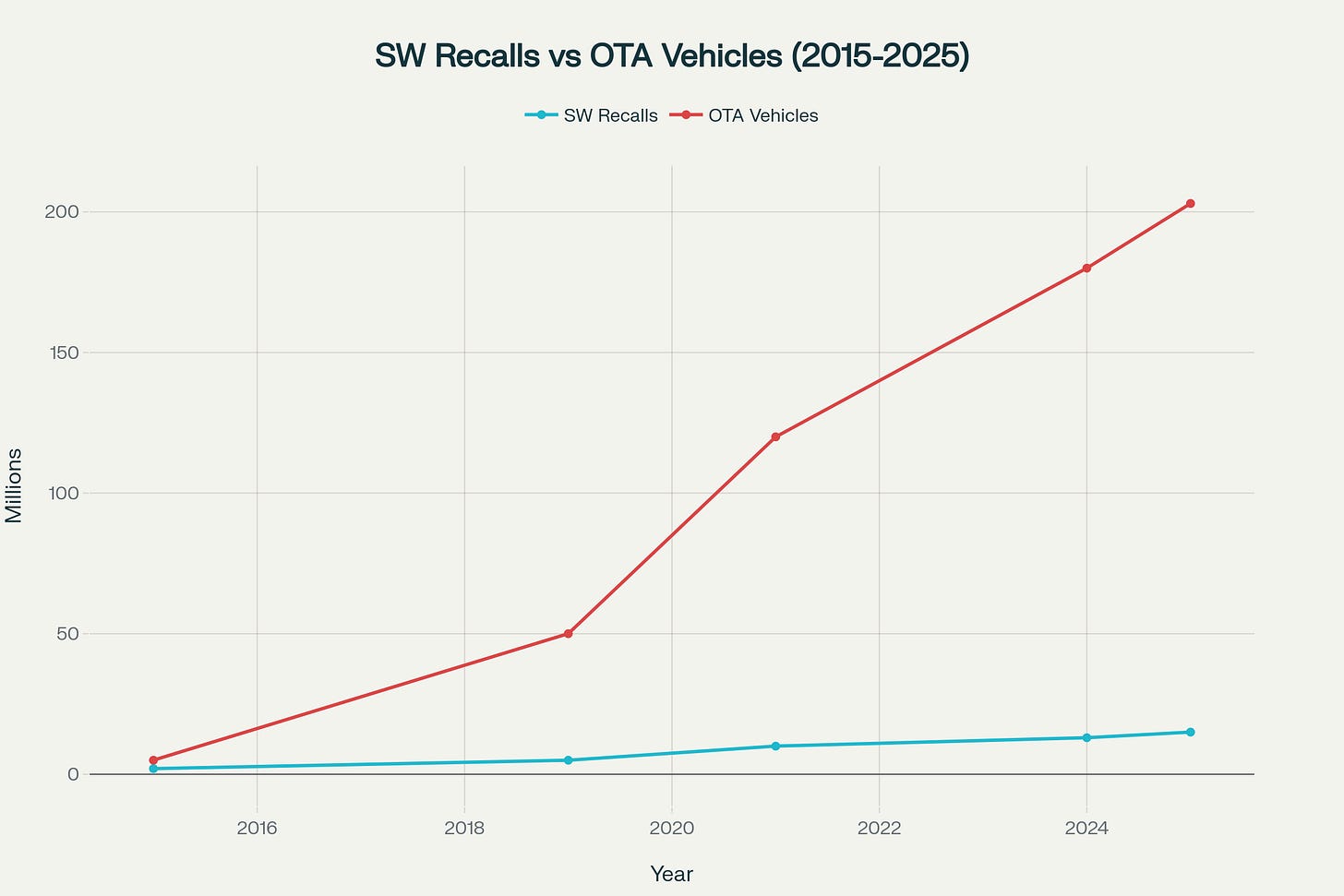

In the race towards smart mobility & Software Defined Vehicles, over-the-air (OTA) software updates have become both a blessing and a curse for carmakers. OTA allows automakers to fix software bugs, recall vehicles, and add dazzling new features —all without requiring the owner to visit a dealership. But, as multiple recent headlines demonstrate, even leaders like Tesla, Volkswagen, and Ford are discovering that botched OTA implementations can bring steep and sometimes invisible costs. Let’s unpack the real-world ROI, accident case studies, and lessons hidden behind the hype.

2. The Dual Promise of OTA: Huge Cost Savings, Faster Fixes

2.1. Quantifying the Upside

OTA updates can cut recall costs by up to 70% compared to physical recalls. Traditionally, an automotive recall costs anywhere from $500 to $2,000 per vehicle, with mass recalls quickly reaching billions in direct costs.

If deployed correctly:

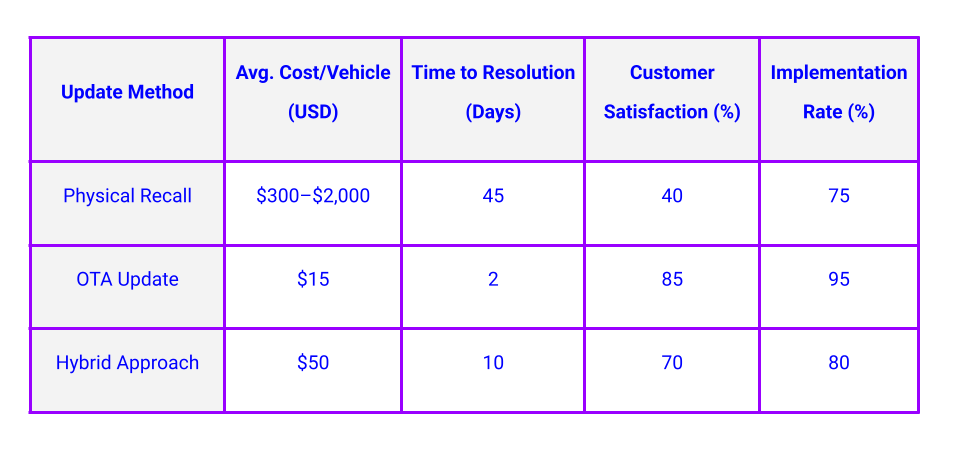

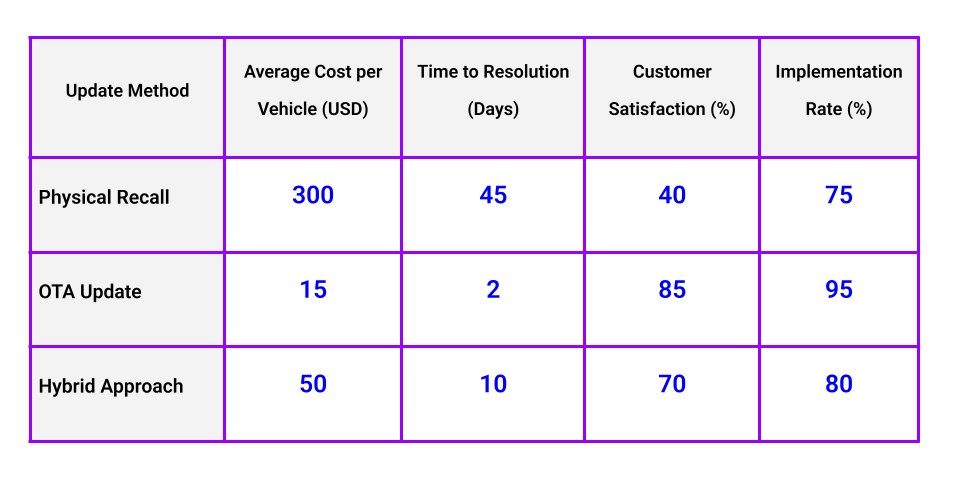

OTA updates cost: about $15/vehicle (vs. $300–$2,000 for physical recall)

Time to fix: 2–3 days (vs. 45+ days for physical repair)

Customer satisfaction: 85% (OTA) vs. 40% (physical recall)

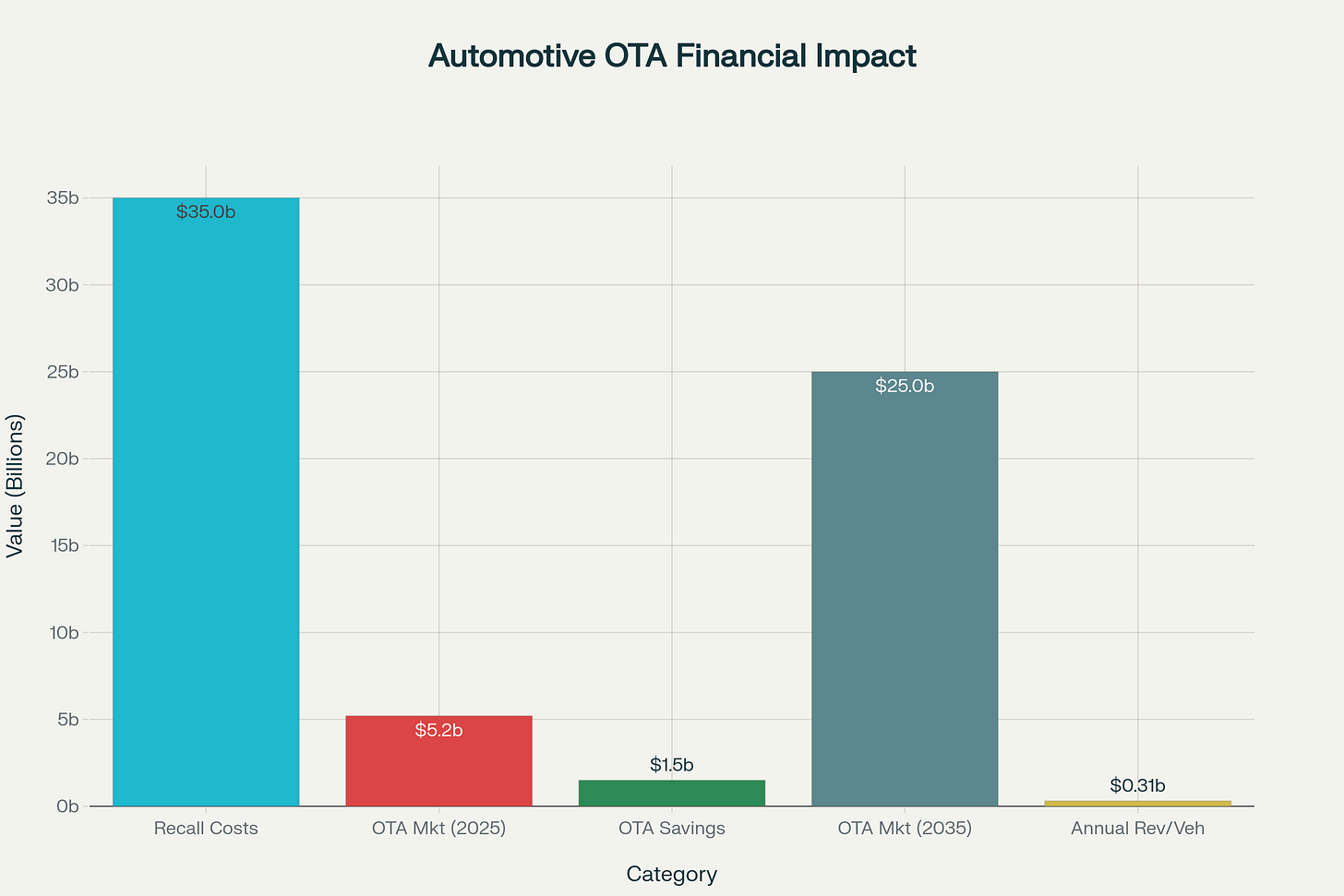

By 2028, the US auto market alone is projected to save $1.5 billion/year with OTA-enabled recalls. Globally, the OTA market will grow from $5.2 billion (2025) to $25 billion by 2035.

2.2. High Stakes: When OTA Goes Wrong

While the benefits are significant, failures are costly. With modern vehicles running over 100 Electronic Control Units (ECUs) and millions of lines of code, a simple mistake can cascade across entire fleets (see Table 1).

Real-World Examples (2020–2025)

Tesla

Phantom Braking Recall (2021): OTA bug in Full Self-Driving beta send false collision warnings to 12,000 vehicles. Tesla halted the update, issued a corrective OTA within a day. Despite agility, the incident triggered a formal NHTSA recall and negative press.

Battery Range Throttling Lawsuit: A 2019 OTA update capped the battery range of 1,743 Teslas for safety, angering users. Result: $1.5 million legal settlement (& lost trust) for Tesla.

Record Recalls (2022): 19 recall campaigns covering 3.8M vehicles. 12/19 issues fixed via OTA – but the public’s perception of “constant recalls” stings brand value.

Volkswagen Group

ID.3, ID.4, and Porsche Taycan Glitches: Lapses in OTA readiness meant many cars in 2020–2023 were physically recalled for software faults. Porsche recalled 43,000 Taycans in 2021 for a bug that could not be fixed OTA; costly and embarrassing for a premium brand.

CARIAD Crisis (2022): Delayed software led to the CEO shakeup, billions lost in R&D, and stock stagnation.

Ford & GM

Ford Mustang Mach-E (2022): Battery contactor flaw issued as OTA “patch.” Regulators later questioned the effectiveness, highlighting OTA’s “good enough” tradeoffs. Ford was fined $165 million in a separate recall for slow compliance.

GM Bolt EV Fires (2021): Hardware recalls for battery fires cost $1.8B, and OTA update temporarily limited charging.

2.3. The Hidden Costs

3. Beyond the Direct Dollar: Brand, Legal & Reputation Fallout

Legal Liability & Settlements: Tesla’s $1.5M for battery throttling, Volvo fined $130M for recall delays.

Stock Market Penalty: NIO’s battery-fire recall (2019) cost 80% market value drop in months. VW, Ford, and others have seen temporary dips following major recall news.

Reputation Damage: Brand loyalty suffers after failed OTAs — studies show customers avoid brands with recent recall histories.

Management Distraction: Software crises diverted R&D from innovation to crisis management.

3.1. Why OTA Still Fails: The Technical Reality

Complex Architectures: Cars now have dozens of ECUs. One update bug can “brick” the whole car.

Connectivity Risks: Failed OTA downloads leave vehicles in limbo. BMW, Polestar, VW, and Rivian have all had incidents of “bricked” or immobilised vehicles.

Calibration for Safety Systems: Updating ADAS, brake, or steering software needs real-world validation; labs miss edge cases.

Cybersecurity: Jeep hack (2015) led to 1.4M vehicle recall. A compromised OTA pipeline could have catastrophic results.

Legacy Architecture: OEMs like VW required dealership fixes for what should have been OTA updates, due to old platforms.

3.2. Lessons Learned & Where the Industry is Headed

OTA Execution = Survival: By 2025, automakers lacking robust OTA lose up to $900M/year in avoidable recall costs.

Investment in Quality Assurance: Carmakers are building "Software SWAT teams" and digital twins to test updates virtually. Software validation is now as critical as crash tests.

Regulation is Coming: NHTSA and China are building new regulatory frameworks to govern vehicle OTA and software recalls (2022–2025). In addition, regulations like the UN.ECE R155 & R156 are for cybersecurity compliance and software update management.

Market is Growing Fast: By 2035, almost all new cars will support OTA; annual industry savings and revenue potential will be massive.

4. Conclusion

OTA updates are not an optional feature; they are now core to the automaker's business model. But the digital tightrope is real: a single failed update can cost millions, tank a stock price, and sink customer trust overnight. The revealed ROI story is this: OTA delivers huge savings and agility, but only for automakers that invest deeply in engineering, security, and crisis readiness. As vehicle software complexity explodes, OTA’s winners will dominate the automotive landscape—while those that fumble may face existential risk.

It is essential to implement systems & critical processes around OTA. Especially while rolling out updates for safety-critical systems. While we say the cars are mobile phones on wheels, they are no less than a robot. Which could cause danger to humans inside & outside. Along with update failure, an improper OTA could enable wrong software, configuration and security for vehicles.

So, OTA shall be designed & implemented with the same care as a safety system..!

5. References

How OTA updates reduce automotive recalls: A cost-saving strategy for software-defined vehicles, Mender.io (2024), Link

OTA updates to fix recalled cars will save OEMs $1.5B, ABI Research (2023), Link

Automotive Over-The-Air (OTA) Updates Market - 2035, Future Market Insights (2025), Link

Automotive Over-the-Air (OTA) Updates Market Revenue and Growth (2025), Maia Research, Link

Tesla, Electrek, Reuters, and NHTSA regulatory releases (2020–2024)

Volkswagen Group, Porsche, Ford, GM software recall and financial disclosure reports (2020–2025)

NIO 2019 investor guidance, Bloomberg (2019)

Polestar, Jeep, Rivian software recall and cybersecurity incidents (2020–2024)

China OTA regulations, Reuters (2024), Link

Recall cost and satisfaction survey, Accenture, KPIT (2025)

Recall Masters 2024 Automotive Recall Report, Recall Masters (2025), Link

“The Hidden Costs: When OTA Goes Wrong,” (2025)

Market and recall cost trend data, eSync Alliance

“Software-Related Recalls and the Auto Industry’s Ongoing Evolution.” WardsAuto (2024), Link

This blog is edited and enhanced with Perplexity & Research supported by ChatGPT