Inside Tesla's Brain before CyberTruck

Exploring Tesla's Electronics Architecture and Compute Chips: The Electronics and Compute Power of FSD and MCU Hardware Before 2023 (Pre-CyberTruck)

1. Introduction

Tesla's electronic and electrical (E/E) architecture represents a paradigm shift in automotive technology. By centralizing vehicle computing, Tesla has achieved unparalleled performance, scalability, and cost-effectiveness. Tesla's innovations in Full Self-Driving (FSD) hardware and MCU (Media Control Unit) computing exemplify its approach to software-defined vehicles. These advancements not only enhance vehicle capabilities but also give Tesla a strategic edge, enabling over-the-air updates, rapid iteration, and streamlined production processes.

2. Benefits of Tesla's Architecture and FSD Hardware

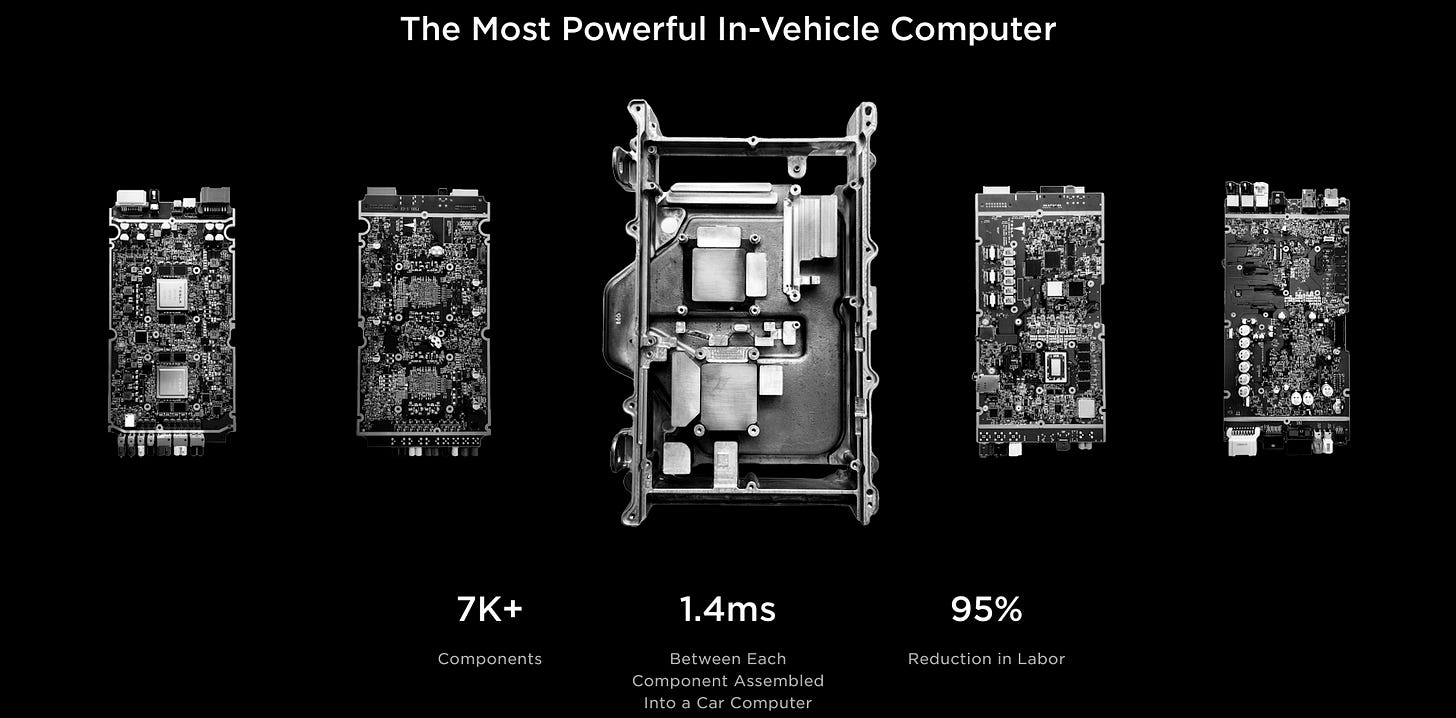

Tesla's centralized architecture, embodied in FSD Hardware 4 (HW4), offers numerous advantages:

Strategic Superiority:

Tesla's architecture allows for rapid feature deployment and bug fixes through over-the-air updates, reducing recall costs and improving customer satisfaction. The vertical integration of hardware and software creates a seamless ecosystem that is difficult for competitors to replicate.Technical Advantages:

Centralized High-Performance Computing: Tesla consolidates functions into fewer, more powerful chips, reducing complexity and improving reliability.

Reduced ECU Count: Compared to legacy automakers, Tesla uses significantly fewer ECUs, as highlighted in a comparison between the Model Y and competitors like the VW ID.4 and Ford Mach E.

Optimized Communication: The adoption of high-speed Ethernet and BroadR-Reach networks enhances data transfer rates and reduces latency.

Advanced Safety Systems: The integration of safety-critical systems ensures compliance with ASIL-D standards, safeguarding against failures.

3. Challenges Faced by Legacy Automakers

Legacy automakers often rely on domain-oriented E/E architectures with multiple specialized ECUs, leading to:

Complexity and Scalability Issues: These architectures struggle to support modern features like ADAS and high-bandwidth infotainment.

Dependency on Tier-1 Suppliers: This results in slower innovation cycles and fragmented software ecosystems.

Missed Opportunities for Centralization: Unlike Tesla, these manufacturers retain legacy ECUs, perpetuating inefficiencies and higher costs.

Tesla's centralized approach illustrates the benefits of starting from scratch. Legacy manufacturers must overcome entrenched practices and adopt zone-oriented architectures or risk falling further behind.

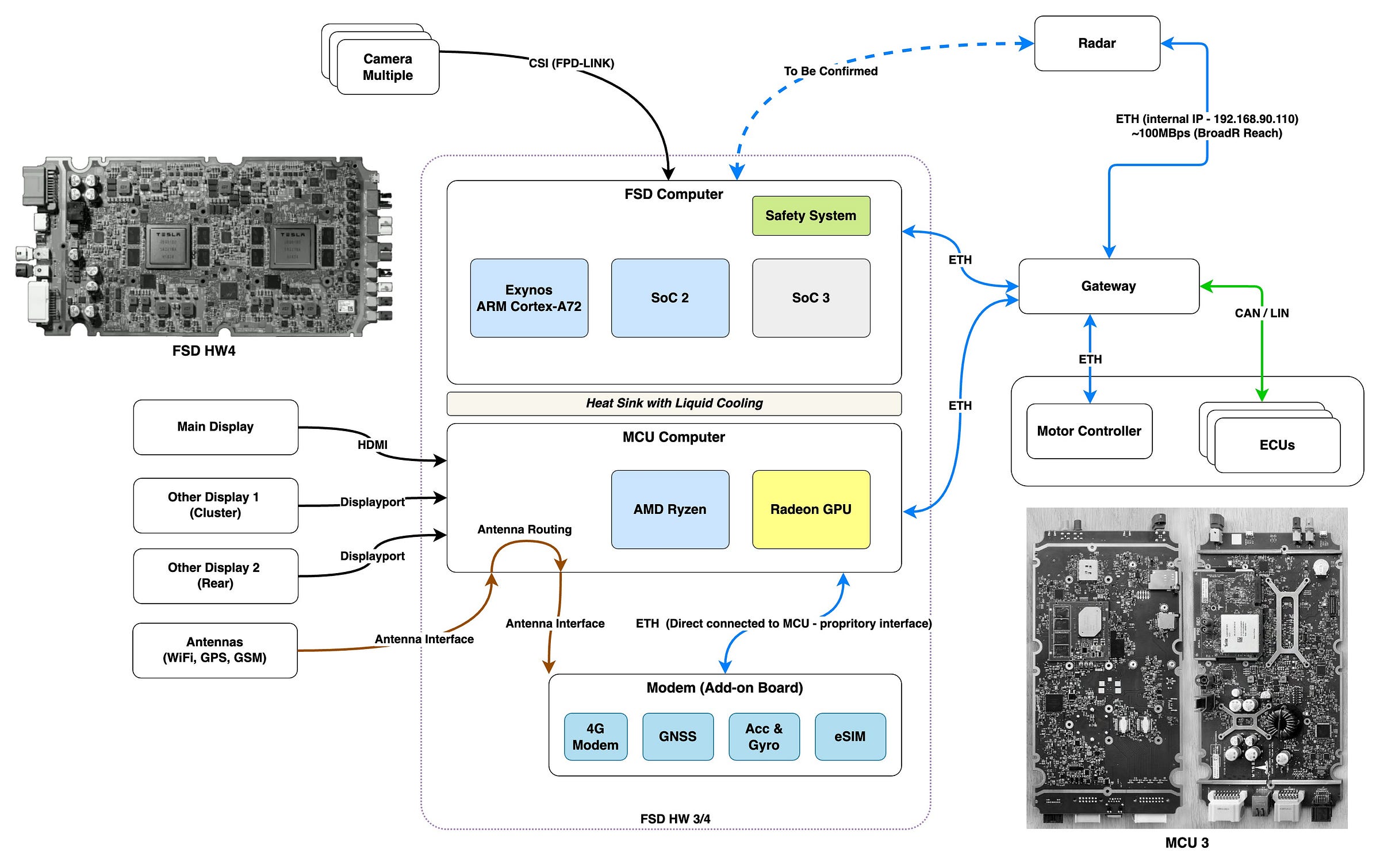

Note: The image of Tesla's hardware architecture presented in this blog is a conceptual representation generated using multiple inputs and sources. While every effort has been made to ensure accuracy, it may include approximations or errors due to the speculative nature of some details.

4. Tesla's HW4 Architecture Explained

Tesla's HW4 architecture integrates the following key components:

FSD Computer:

Dual SoCs: Exynos ARM Cortex-A72 paired with SoC 2 and SoC 3(optional) ensure high redundancy and computing power.

Safety Systems: A dedicated safety system isolates critical functions, enhancing reliability.

Camera Inputs: Utilizing FPD-Link technology, Tesla connects multiple cameras for its full self-driving capabilities.

MCU Computer:

AMD Ryzen Processor: Provides robust processing power for infotainment and vehicle controls.

Radeon GPU: Ensures high-quality graphics for displays.

Communication Networks:

High-speed Ethernet links facilitate communication between the FSD computer, gateway, motor controller, and ECUs.

CAN and LIN protocols are retained for compatibility with legacy subsystems.

Modem Integration:

A 4G modem, GNSS module, and eSIM enable seamless connectivity for vehicle-to-cloud communication.

This architecture underscores Tesla's emphasis on scalability, reliability, and future-proofing through centralization and high-speed networking.

5. Lessons for Legacy Automakers

Legacy automakers can learn from Tesla's approach by:

Reducing ECU Count: Consolidating functions into fewer, more powerful controllers.

Adopting Modern Networks: Transitioning to Ethernet-based communication for faster and more reliable data transfer.

Embracing Software-Defined Architectures: Building flexible systems capable of over-the-air updates and modular software upgrades.

Focusing on Vertical Integration: Developing in-house expertise in hardware and software to reduce reliance on suppliers.

Volkswagen's investment in Rivian (earlier in the software development division CARID) and Ford's restructuring efforts indicate a recognition of these imperatives, but significant challenges remain.

6. Conclusion and Future Topics

Tesla's HW4 architecture demonstrates the benefits of centralized computing, reduced complexity, and high-performance networking. While legacy automakers face challenges in transitioning to such architectures, Tesla's approach serves as a roadmap for modernization.

In an upcoming blog, discussions will explore Tesla's 48V Etherloop system and its post-CyberTruck advancements in vertical integration.

7. References

Munro, S. et al., "Comparing Tesla, Ford, & VW's Electrical Architectures," 3IS Inc., YouTube.

Tesla Autopilot Hardware, Wikipedia, Link.

NotATeslaApp, "Tesla’s Hardware 4: Unraveling the Mystery Behind the Most Advanced FSD Computer," Link.

"Methodical Approach for Centralization Evaluation of Modern Automotive E/E Architectures," Lucas Mauser et al., PDF.

This blog is edited and enhanced with ChatGPT 4o